外六角螺絲

外六角螺絲

外六角螺絲

外六角螺絲

外六角螺絲,也稱為六角頭螺絲(Hex Head Screws),具有六角形的頭部,通常需要使用六角扳手或扭力扳手來旋緊或鬆開。這種頭部設計提供了更好的扭矩控制,使其適用於需要更大力量的應用。以下是一些關於外六角螺絲的更多信息:

頭部形狀:外六角螺絲的頭部是一個六邊形凸起,通常帶有一個中央的孔,以便於使用扭力工具。

使用工具:安裝或拆卸外六角螺絲時,您需要使用六角扳手、扭力扳手或六角扳手套筒。這些工具可以提供良好的扭矩控制,使您能夠更容易地調整螺絲的緊固力度。

材料:外六角螺絲可以由各種材料製成,包括鋼、不銹鋼、黃銅、銅和塑料,具體材料的選擇取決於應用需求。

防銹處理:對於外六角螺絲,特別是用於戶外或潮濕環境的應用,可以選擇具有防銹處理的螺絲,以增加其耐用性。

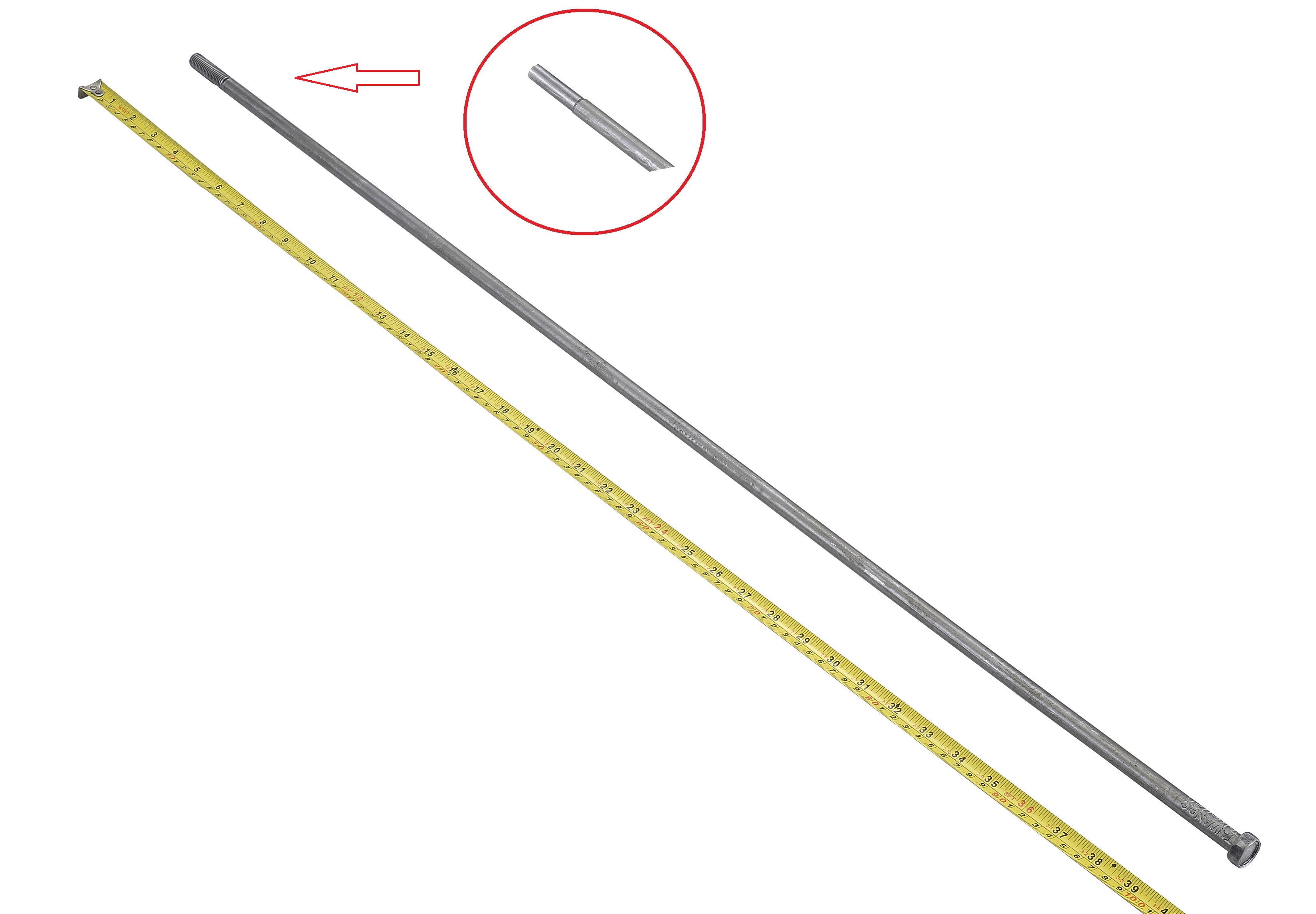

尺寸:外六角螺絲具有各種不同的尺寸,包括直徑(從小到大)和長度。選擇適當的尺寸是確保連接安全的關鍵。

應用:外六角螺絲廣泛應用於建築、機械、汽車、家具、家庭維修等各種應用中,特別是當需要高扭矩和強固連接時。

安裝和保養:在安裝外六角螺絲時,要確保使用正確的工具,以避免損壞螺絲頭。定期檢查並緊固外六角螺絲,以確保連接的穩固性。

外六角螺絲是一種強固的連接元件,特別適用於需要高扭矩和可靠連接的應用。選擇適當的尺寸和材料,並使用正確的工具,可以確保項目的成功和安全。如果您對特定應用或外六角螺絲的進一步問題有任何疑問,請隨時提供更多詳細信息,我將竭盡所能提供進一步的幫助。

螺絲的硬度:外六角螺絲的硬度通常由材料和處理方法確定。高硬度的螺絲更耐磨,可以承受更大的扭矩。

耐腐蝕特性:如果外六角螺絲將在潮濕或腐蝕性環境中使用,則建議選擇不銹鋼或其他耐腐蝕處理的螺絲,以防止生銹。

外六角螺絲的種類:根據不同的需求,外六角螺絲有多種種類,包括六角螺絲、六角鉚接螺絲、六角肩螺絲、六角螺母等。

自攻螺絲和外六角螺絲的比較:儘管自攻螺絲和外六角螺絲都具有六角頭,但它們的工作方式不同。自攻螺絲可以自行穿透材料,而外六角螺絲需要預先鑽孔。

應用領域:外六角螺絲在需要高度可靠連接的場合非常常見,如機械設備、車輛製造、建築結構和金屬結構等。

螺絲的重複使用:與自攻螺絲不同,外六角螺絲通常可以多次使用,前提是頭部未受損。

外六角螺絲的安全注意事項:在使用外六角螺絲時要小心,避免過度扭矩,以免造成損壞或危險。

自攻螺絲和外六角螺絲的選擇:選擇自攻螺絲還是外六角螺絲取決於具體的應用和需求。如果需要螺絲自行穿過材料,則自攻螺絲可能更適合;而如果需要高度可靠的連接,則外六角螺絲可能更適合。

無論您是專業工人還是進行DIY項目,了解外六角螺絲的特性和選擇的可能性可以幫助您做出明智的選擇,確保項目的成功和安全。如果您對特定應用或外六角螺絲的進一步問題有任何疑問,請隨時提供更多詳細信息,我將竭盡所能提供進一步的幫助。

外六角螺絲的使用優勢:外六角螺絲的六角頭設計提供了優越的扭矩控制,使得在高扭矩需求的應用中,例如汽車引擎組裝和機械工程,它們非常有用。

標準規格:外六角螺絲通常符合國際標準,例如ISO 4014和ISO 4017。這些標準規定了螺絲的尺寸、螺紋規格和性能要求,以確保一致性和互換性。

外六角螺絲的安裝步驟:安裝外六角螺絲時,通常需要將螺絲的六角頭插入六角扳手或扭力扳手,然後旋緊或鬆開。扭矩扳手是確保螺絲被正確安裝的有用工具,因為它們可以提供精確的扭矩控制。

特殊用途的外六角螺絲:有些外六角螺絲被設計用於特殊用途,例如高強度結構連接、機械設備的裝配、車輛的維修等。這些特殊用途的螺絲可能具有特殊的材料、鍍層或硬度。

外六角螺絲的抗震性:由於外六角螺絲提供了可靠的扭矩控制,它們在需要抗震性的應用中非常有用,例如地震區域的建築。

質量控制:選擇信譽良好的制造商和供應商以確保外六角螺絲的質量。質量控制對於確保連接的強度和安全性至關重要。

適用性:外六角螺絲適用於多種材料,包括金屬、木材、塑料和複合材料。選擇適當的外六角螺絲以適應具體的應用和材料。

專業建議:在進行具有特殊要求或複雜應用的工程項目時,建議諮詢專業人員或工程師,以確保選擇和安裝的外六角螺絲符合標準和需求。

外六角螺絲是一種廣泛使用的連接元件,其特性使其適用於各種高強度連接需求的應用。選擇適當的外六角螺絲型號、尺寸和特性,以及使用正確的工具,可以確保工程的成功和安全。如果您對特定應用或外六角螺絲的進一步問題有任何疑問,請隨時提供更多詳細信息,我將竭盡所能提供進一步的幫助。

外六角螺絲的長度:外六角螺絲的長度通常根據應用需求而變化。請確保選擇適當長度的螺絲以確保安全和可靠的連接。

外六角螺絲的設計創新:一些外六角螺絲具有創新的設計,例如六角螺絲帶有密封垫圈或防漏結構,可用於防水或防滲漏應用。

防盗外六角螺絲:在某些情況下,外六角螺絲被用於需要安全性的應用。防盗外六角螺絲具有特殊的設計,防止普通工具使用。

安全注意事項:在使用外六角螺絲時,請小心避免過度扭矩,以免損壞螺絲或連接材料。

外六角螺絲的標準:外六角螺絲通常遵循標準規格,例如ISO 4014、ISO 4017、DIN 933和DIN 931等。了解這些標準可以幫助您選擇合適的螺絲。

外六角螺絲的耐久性:外六角螺絲通常具有良好的耐久性,但在特殊環境中可能需要定期檢查和保養,以確保連接的穩固性。

外六角螺絲的規格標示:外六角螺絲的尺寸和規格通常會在其表面或包裝上標示。請確保查看這些信息以選擇適當的螺絲。

外六角螺絲是一種多功能的連接元件,廣泛用於各種應用中。選擇適當的外六角螺絲型號、尺寸和特性,並遵循安全和規格要求,可以確保項目的成功和可靠的連接。如果您對特定應用或外六角螺絲的進一步問題有任何疑問,請隨時提供更多詳細信息,我將竭盡所能提供進一步的幫助。

外六角螺絲的適用范圍:外六角螺絲廣泛應用於機械、建筑、汽車、自行車、家具製造、木工和金屬工程等眾多領域。它們是一種多功能的連接元件。

六角螺絲與六角螺母:外六角螺絲通常需要與六角螺母一起使用。確保選擇與螺絲尺寸相配的螺母以實現正確的連接。

特殊用途的外六角螺絲:某些外六角螺絲設計用於特殊用途,例如高溫環境、高壓環境或具有抗腐蝕性的要求。這些螺絲可能需要特殊的材料和處理。

定制的外六角螺絲:在某些情況下,您可能需要訂製特殊尺寸或特殊材料的外六角螺絲,以滿足特定的工程需求。

外六角螺絲的可重複使用性:外六角螺絲通常可以多次安裝和拆卸,前提是它們未受損或磨損。

螺絲的材料硬度:外六角螺絲的硬度可以根據具體需求調整。高硬度的螺絲更適用於高強度連接。

外六角螺絲的配件:在某些情況下,外六角螺絲可能需要配合使用螺絲墊圈或螺絲膠等配件,以提供額外的連接特性。

螺絲的價格和供應商:外六角螺絲的價格因材料、尺寸和質量而異。選擇可靠的供應商以確保質量和供貨可靠性。

外六角螺絲是一種強大的連接工具,適用於各種應用。了解其特性、尺寸和使用注意事項,以及根據具體項目需求選擇適當的型號和材料,可以確保工程的成功和可靠的連接。如果您對特定應用或外六角螺絲的進一步問題有任何疑問,請隨時提供更多詳細信息,我將竭盡所能提供進一步的幫助。

外六角螺絲的緊固方法:安裝外六角螺絲時,通常需要使用六角扳手、扭力扳手或六角套筒來提供扭矩。正確的扭矩控制非常重要,以確保連接的穩固性。

外六角螺絲的緊固步驟:緊固外六角螺絲時,應該先輕輕旋緊,然後再施加正確的扭矩。這可以幫助避免過度扭矩造成損壞。

外六角螺絲的尺寸標示:外六角螺絲的尺寸通常以直徑(d)和長度(L)來標示,例如M8x30表示直徑為8毫米,長度為30毫米的螺絲。

外六角螺絲的耐磨性:外六角螺絲通常具有良好的耐磨性,因此它們在高磨損的機械應用中非常有用。

螺絲的包裝方式:外六角螺絲可以以單個螺絲、螺絲帶、螺絲盒或螺絲桶等不同的包裝方式提供,根據您的需求和使用習慣選擇合適的包裝。

外六角螺絲的安全性:在使用外六角螺絲時,要小心避免尖端损坏或扭矩过大,以免引起安全问题。

應用範例:外六角螺絲可用於車輛製造、航空航天、電子設備、體育用品、建筑結構等各種領域。

專業建議:如果您在具體應用中不確定該選擇哪種外六角螺絲,建議諮詢專業人士或工程師,以確保符合應用需求。

外六角螺絲是一種多功能的連接元件,可適用於各種應用。根據您的具體需求和應用,選擇適當的型號、尺寸和特性,並使用正確的工具,以確保連接的穩固和安全。如果您對特定應用或外六角螺絲的進一步問題有任何疑問,請隨時提供更多詳細信息,我將竭盡所能提供進一步的幫助。

Hexagonal screws, also known as Hex Head Screws, have a hexagonal head and usually require the use of a hexagonal wrench or torque wrench to tighten or loosen. This head design provides better torque control, making it suitable for applications requiring greater power. Here is some more information about external hexagonal screws:

Head shape: The head of an external hexagonal screw is a hexagonal protrusion, usually with a hole in the center to facilitate the use of torque tools.

Tools to use: When installing or removing hex screws, you'll need a hex wrench, torque wrench, or hex wrench socket. These tools provide good torque control, allowing you to adjust the tightening strength of the screw more easily.

Materials: External hex screws can be made from a variety of materials, including steel, stainless steel, brass, copper and plastic, with the specific material chosen depending on the application needs.

Anti-rust treatment: For external hexagonal screws, especially for applications in outdoor or humid environments, you can choose screws with anti-rust treatment to increase their durability.

Sizes: External hex screws come in a variety of sizes, including diameter (small to large) and length. Choosing the proper size is key to ensuring a secure connection.

Applications: External hexagonal screws are widely used in various applications such as construction, machinery, automobiles, furniture, home repairs, etc., especially when high torque and strong connections are required.

Installation and Maintenance: When installing hex screws, be sure to use the correct tools to avoid damaging the screw heads. Regularly check and tighten the external hexagonal screws to ensure the stability of the connection.

The external hexagonal screw is a strong connecting element particularly suitable for applications requiring high torque and reliable connections. Choosing the appropriate sizes and materials, and using the right tools, can ensure a successful and safe project. If you have any further questions about a specific application or external hex screws, please feel free to provide more details and I will do my best to provide further assistance.

Hardness of Screws: The hardness of external hexagonal screws is usually determined by the material and processing method. High-hardness screws are more wear-resistant and can withstand greater torque.

Corrosion-resistant properties: If the external hexagonal screws will be used in a humid or corrosive environment, it is recommended to choose stainless steel or other corrosion-resistant treated screws to prevent rust.

Types of external hexagonal screws: According to different needs, there are many types of external hexagonal screws, including hexagonal screws, hexagonal riveting screws, hexagonal shoulder screws, hexagonal nuts, etc.

Comparison of self-tapping and hexagonal screws: Although both self-tapping and hexagonal screws have hex heads, they work differently. Self-tapping screws can penetrate the material on their own, whereas hex screws require pre-drilling holes.

Application fields: External hexagonal screws are very common in situations where highly reliable connections are required, such as mechanical equipment, vehicle manufacturing, building structures, and metal structures.

Reuse of screws: Unlike self-tapping screws, hex screws can usually be used multiple times, provided the heads are not damaged.

Safety precautions for hexagonal screws: Be careful when using hexagonal screws to avoid excessive torque, which may cause damage or danger.

Choice of self-tapping screws and external hexagonal screws: Choosing between self-tapping screws and external hexagonal screws depends on the specific application and needs. If the screw is required to penetrate the material on its own, self-tapping screws may be more suitable, whereas if a highly reliable connection is required, external hex screws may be more suitable.

Whether you are a professional worker or undertaking a DIY project, understanding the characteristics and selection possibilities of hex screws can help you make an informed choice, ensuring the success and safety of your project. If you have any further questions about a specific application or external hex screws, please feel free to provide more details and I will do my best to provide further assistance.

Advantages of using external hexagonal screws: The hexagonal head design of external hexagonal screws provides superior torque control, making them very useful in applications with high torque requirements, such as automotive engine assembly and mechanical engineering.

Standard specifications: External hexagonal screws usually comply with international standards such as ISO 4014 and ISO 4017. These standards specify screw dimensions, thread specifications and performance requirements to ensure consistency and interchangeability.

Installation steps of external hexagonal screws: When installing external hexagonal screws, you usually need to insert the hexagonal head of the screw into a hexagonal wrench or torque wrench, and then tighten or loosen it. Torque wrenches are useful tools for ensuring screws are installed correctly because they provide precise torque control.

Special-purpose external hexagonal screws: Some external hexagonal screws are designed for special purposes, such as high-strength structural connections, assembly of mechanical equipment, vehicle maintenance, etc. These special purpose screws may have special materials, coatings or hardnesses.

Seismic Resistance of Hex Screws: Because hex screws provide reliable torque control, they are useful in applications that require seismic resistance, such as construction in earthquake zones.

Quality Control: Choose reputable manufacturers and suppliers to ensure the quality of hexagon socket screws. Quality control is critical to ensure the strength and security of the connection.

Suitability: External hex screws are suitable for use in a variety of materials, including metal, wood, plastic and composite materials. Select the appropriate external hex screw to suit the specific application and material.

Professional advice: When undertaking engineering projects with special requirements or complex applications, it is recommended to consult professionals or engineers to ensure that the selected and installed external hexagonal screws meet standards and requirements.

The external hexagonal screw is a widely used connecting element whose characteristics make it suitable for a variety of applications with high-strength connection requirements. Choosing the appropriate type, size and characteristics of hexagonal socket head screws, as well as using the correct tools, ensures a successful and safe project. If you have any further questions about a specific application or external hex screws, please feel free to provide more details and I will do my best to provide further assistance.

Length of Hex Screws: The length of hex screws often varies based on application requirements. Please make sure to choose appropriate length screws to ensure a safe and secure connection.

Design innovation of external hexagonal screws: Some external hexagonal screws have innovative designs, such as hexagonal screws with sealing gaskets or leak-proof structures, which can be used in waterproof or anti-leakage applications.

Anti-Theft Hex Screws: In some cases, hex screws are used in applications that require security. Anti-theft external hexagonal screws have a special design to prevent the use of ordinary tools.

Safety Note: When using external hexagonal screws, be careful to avoid excessive torque to avoid damaging the screws or connecting material.

Standards for external hexagonal screws: External hexagonal screws usually follow standard specifications, such as ISO 4014, ISO 4017, DIN 933 and DIN 931, etc. Understanding these standards can help you choose the right screws.

Durability of external hexagonal screws: External hexagonal screws generally have good durability, but in special environments they may require regular inspection and maintenance to ensure the stability of the connection.

Specification marking of external hexagonal screws: The size and specifications of external hexagonal screws are usually marked on their surface or packaging. Be sure to review this information to select the appropriate screws.

The external hexagonal screw is a versatile connecting element used in a wide variety of applications. Selecting the appropriate external hex screw type, size and characteristics, and following safety and specification requirements, can ensure a successful project and a reliable connection. If you have any further questions about a specific application or external hex screws, please feel free to provide more details and I will do my best to provide further assistance.

Scope of application of external hexagonal screws: External hexagonal screws are widely used in many fields such as machinery, construction, automobiles, bicycles, furniture manufacturing, woodworking and metal engineering. They are a versatile connecting element.

Hexagonal screws and hexagonal nuts: External hexagonal screws usually need to be used with hexagonal nuts. Make sure to choose a nut that matches the size of the screw for a proper connection.

Special purpose hexagonal screws: Some hexagonal screws are designed for special purposes, such as high temperature environments, high pressure environments, or corrosion resistance requirements. These screws may require special materials and handling.

Customized hexagonal screws: In some cases, you may need to order hexagonal screws in special sizes or materials to meet specific project needs.

Reusability of hex screws: Hex screws can usually be installed and removed multiple times, provided they are not damaged or worn.

Material hardness of screws: The hardness of external hexagonal screws can be adjusted according to specific needs. High-hardness screws are more suitable for high-strength connections.

Accessories for external hexagonal screws: In some cases, external hexagonal screws may require the use of accessories such as screw washers or screw glue to provide additional connection characteristics.

Screw Prices and Suppliers: Hex screw prices vary based on material, size, and quality. Choose reliable suppliers to ensure quality and supply reliability.

The external hexagonal screw is a powerful joining tool suitable for a variety of applications. Understanding their characteristics, dimensions and usage considerations, as well as selecting the appropriate model and material based on specific project needs, can ensure a successful project and reliable connections. If you have any further questions about a specific application or external hex screws, please feel free to provide more details and I will do my best to provide further assistance.

Tightening method of external hexagonal screws: When installing external hexagonal screws, you usually need to use a hexagonal wrench, torque wrench or hexagonal socket to provide torque. Proper torque control is very important to ensure a secure connection.

Steps for tightening external hexagonal screws: When tightening external hexagonal screws, you should first tighten them lightly and then apply the correct torque. This can help avoid damage from excessive torque.

Size indication of external hexagonal screws: The size of external hexagonal screws is usually indicated by diameter (d) and length (L). For example, M8x30 means a screw with a diameter of 8 mm and a length of 30 mm.

Wear resistance of hexagonal screws: Hexagonal screws generally have good wear resistance, so they are very useful in high-wear mechanical applications.

Packaging methods of screws: External hexagonal screws can be provided in different packaging methods such as single screws, screw tapes, screw boxes or screw barrels. Choose the appropriate packaging according to your needs and usage habits.

Safety of hexagonal screws: When using hexagonal screws, be careful to avoid tip damage or excessive torque, which may cause safety issues.

Application examples: External hexagonal screws can be used in various fields such as vehicle manufacturing, aerospace, electronic equipment, sporting goods, and building structures.

Professional advice: If you are not sure which external hexagonal screw to choose for a specific application, it is recommended to consult a professional or engineer to ensure that it meets the application requirements.

The external hexagonal screw is a versatile connecting element that can be used in a variety of applications. Choose the appropriate model, size and features based on your specific needs and application, and use the right tools to ensure a strong and secure connection. If you have any questions about a specific application or further questions about hex screws, please feel free to provide more details and I will do my best to provide further assistance.