特殊螺絲

特殊螺絲

特殊螺絲

特殊螺絲開發製造

Special screw development and manufacturing

特殊螺絲

特殊螺絲

特殊螺絲開發製造

Special screw development and manufacturing

特殊螺絲開發製造

Special screw development and manufacturing

特殊螺絲

特殊螺絲開發製造

Special screw development and manufacturing

特殊螺絲

特殊螺絲開發製造

Special screw development and manufacturing

特殊螺絲

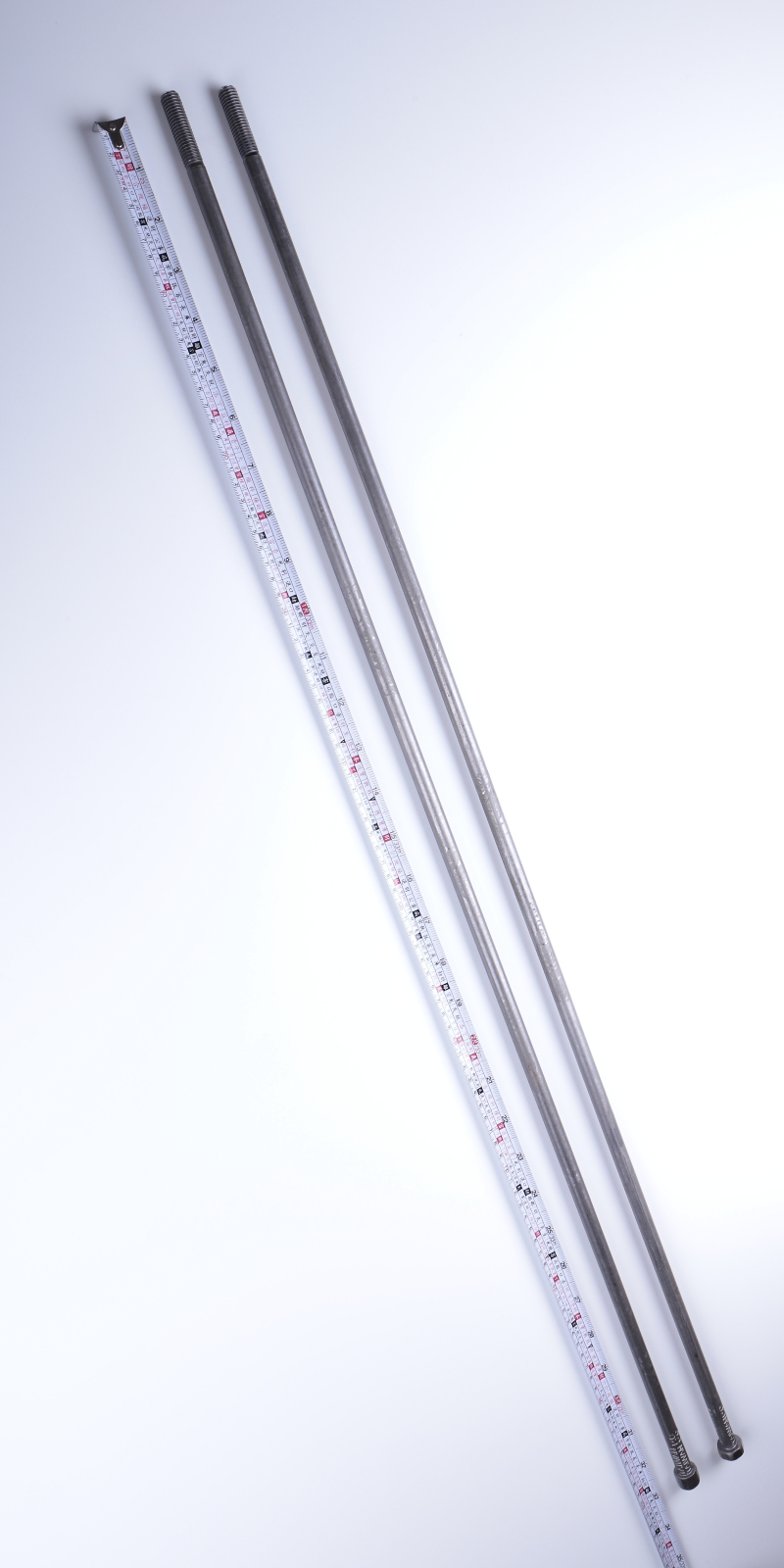

特殊螺絲是一種特殊規格的螺絲,它們有助於解決現代工業和工程上的多種問題。特殊螺絲的特點有:它們的特殊形狀可以提供較強的配合性,抗震性增強,它們的外形也具有很高的美觀性和可靠性。

特殊螺絲可以用於各種用途,例如:機械設備,建材,工具

我們是專業螺絲製造廠 ,提供特殊螺絲的設計和製造服務,我們可以按照客戶的特殊要求來設計和生產特殊螺絲。可以製造出具有特殊形狀、特殊材質、特殊尺寸和特殊表面處理的特殊螺絲,以滿足客戶的特殊要求。

此外,特殊螺絲的設計與製造過程還需要經過多個步驟,其中包括:首先,專業螺絲製造廠會根據客戶的特殊要求,按照一定的規格設計特殊螺絲的圖紙;其次,專業螺絲製造廠會根據設計的圖紙,將特殊螺絲的零件加工出來;最後,專業螺絲製造廠會將這些零件組裝起來,完成特殊螺絲的製造。

總的來說,特殊螺絲是一種用於解決各種問題的特殊規格的螺絲,它們可以用於各種用途,並且可以按照客戶的特殊要求來設計和製造。而專業螺絲製造廠也提供了特殊螺絲的相關服務,為客戶提供最優質的產品和服務。

"特殊螺絲" 這個術語通常用來描述那些在標準螺絲之外,具有特殊設計、尺寸、形狀或用途的螺絲。這些螺絲通常是為滿足特定工程、製造或應用需求而定制或製造的。以下是一些可能屬於特殊螺絲的例子:

特殊材料螺絲:某些特殊應用需要使用非常特殊的材料螺絲,如高溫合金、陶瓷螺絲、複合材料螺絲等。這些材料螺絲可以在極端環境下工作,例如高溫、腐蝕或特殊化學環境。

特殊尺寸螺絲:某些工程需要非標準尺寸的螺絲,可能是非常小或非常大的螺絲,以滿足具體的製造需求。

自攻螺絲:自攻螺絲通常具有尖銳的頂端,可以直接在材料表面穿孔,而不需要先鑽孔。這些螺絲通常用於金屬、塑料和木材中,以便快速連接。

螺釘螺絲:螺釘螺絲通常用於木工項目中,它們具有特殊的螺紋設計,以提供更好的抓地力和固定力。

內螺絲和外螺絲:內螺絲通常是中空的,而外螺絲是內部孔洞的螺絲,這些螺絲通常用於特殊的連接需求,如組合家具。

防盜螺絲:這些螺絲具有特殊的設計,以增加安全性,通常用於保護財產或設備不受盜竊。

特殊頭部螺絲:特殊頭部的螺絲,如六角頭、星形頭、飛碟頭等,可以提供不同的拧緊方式,適合不同的工具或應用。

絕緣螺絲:用於電子或電氣應用,這些螺絲具有絕緣材料製成,以防止電流流動。

特殊螺絲的設計和用途多種多樣,取決於具體的應用需求。如果您需要更具體的信息或有關特定種類的特殊螺絲的問題,請提供更多背景信息,我將盡力提供更多幫助。

當涉及到特殊螺絲時,以下是更多可能的例子和相關信息:

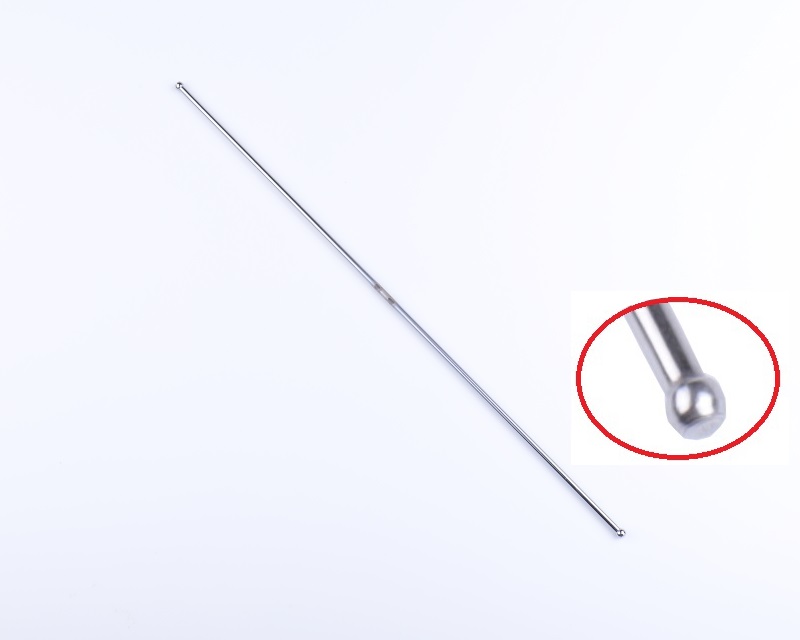

微型螺絲:這些是非常小的螺絲,通常用於微型電子設備、手錶、眼鏡等精密應用。它們的尺寸通常以微米或亞毫米來衡量。

波形螺絲:這些螺絲具有波形或齒輪狀的螺紋,通常用於需要防止自行鬆脫的應用,如自行車螺絲、機動車螺絲等。

光學螺絲:在光學設備和儀器中,需要高度精確的螺絲,以實現精確的對焦和校準。

熱螺絲:用於高溫環境的特殊應用,這些螺絲通常由高溫合金製成,能夠在極端溫度下保持穩定性。

帶防水密封的螺絲:在需要防水或密封性能的場合,這些螺絲通常配有特殊的密封墊圈或塗層,以確保材料不會進入或液體不會滲入。

特殊塗層螺絲:這些螺絲可能帶有抗腐蝕、防刮損或其他特殊塗層,以增加其耐用性和性能。

無頭螺絲:這些螺絲通常用於需要平頭或銳利末端的應用,例如在固定平面表面或特殊支架上。

鉸鏈螺絲:用於具有擴展功能的應用,例如車門鉸鏈或可調節的機械部件。

結構螺絲:用於建築和結構工程中,通常具有高強度和耐用性,以支撐結構元件。

複合螺絲:具有多種功能或特點的螺絲,例如同時具有防盜和絕緣特性的螺絲。

這些是一些特殊螺絲的例子,每種螺絲都具有特定的設計和用途,以滿足各種不同的工程和應用需求。特殊螺絲的使用通常需要仔細考慮其性能特點和材料,以確保它們能夠達到所需的效果。

螺絲環:這些螺絲是帶有環狀頂部的,通常用於吊掛和固定事物。它們經常用於吊掛吊燈、畫作或其他裝飾品。

垂直升降螺絲:這些螺絲通常具有自動上升和下降功能,用於升降平臺、升降椅等應用中。

防震螺絲:這些螺絲通常帶有彈簧或其他減震設計,用於減輕振動和震動,例如在機械和電子設備中。

破裂螺絲:這些螺絲被設計成在達到特定扭矩或負載時自動斷裂,以提供可控的安全特性,例如在安全系統中。

特殊形狀螺絲:有時螺絲的頂部或螺紋具有非標準的形狀,以滿足特殊的連接需求,如U形螺絲、T形螺絲等。

絕緣螺絲:這些螺絲通常用於電氣或電子應用中,以防止電流流動或提供絕緣性能。

自鑽螺絲:這些螺絲具有特殊的鑽頭,可以在穿過材料時同時鑽孔和固定,通常用於金屬和屋頂安裝。

可調螺絲:這些螺絲具有可調節的頂部或螺紋,允許使用者根據需要調整長度或連接。

高強度螺絲:設計用於高強度應用,如航空、汽車製造或建築工程,通常使用特殊的高強度材料。

螺絲孔塞:這些螺絲具有封閉或堵塞螺絲孔的功能,用於密封或防止材料流出。

雙頭螺絲:有螺紋的兩個頂部,通常用於連接兩個物件。

諸如此類的特殊螺絲具有各種特點和用途,可以根據具體的工程和製造需求進行選擇。對於特殊應用,通常需要仔細考慮螺絲的特性,以確保它們能夠實現所需的功能和性能。

安全螺絲:這些螺絲通常具有特殊的設計,需要特殊工具或技術才能拆卸,以提高安全性,通常用於防止未經授權的開啟或拆卸。

波形螺絲:這些螺絲的螺紋呈波浪形狀,用於特殊的抓地力要求,如汽車輪胎。

壓縮螺絲:具有特殊設計,用於在應用中產生壓力,如夾緊元件。

鏈條螺絲:這些螺絲具有特殊的連接方式,可以形成連鎖或鏈條結構。

細牙螺絲:螺絲的螺紋非常細密,用於特殊的精密應用,如光學和儀器。

鎖緊螺絲:具有自鎖功能,可以防止在振動或運動中自行鬆脫。

嵌入式螺絲:用於在材料中嵌入並固定,通常在複合材料或塑料中使用。

熱螺絲:用於高溫應用,具有高溫抗性,例如在熱處理過程中。

橡膠墊螺絲:帶有橡膠墊的螺絲,用於提供密封性能或減震效果。

高精度螺絲:非常精確的製造,用於需要高度精確性的應用,如航空和醫療設備。

防腐蝕螺絲:經過特殊處理以提高其抗腐蝕性,通常在潮濕或腐蝕性環境中使用。

這些是特殊螺絲的一些例子,它們都具有不同的設計和特點,可滿足各種特定應用的需求。選擇正確的特殊螺絲取決於具體的項目和使用情境,通常需要根據工程要求和性能需求進行選擇。

鐵螺絲:這些螺絲通常用於木工和建築應用,具有高度的耐腐蝕性和抗拉伸強度。

螺絲扣:帶有螺絲孔和螺絲的特殊設計,通常用於夾持或固定物體。

自動化螺絲:用於自動化裝配系統中,可以自動鎖定或拧緊,提高生產效率。

空心螺絲:具有中空設計,通常用於輕量化設計或需要減輕重量的應用。

特殊塗層螺絲:具有抗腐蝕、抗刮損或其他特殊塗層,以提供額外的保護和耐用性。

噴漆螺絲:用於需要螺絲與周圍材料匹配外觀的應用,如家具組裝。

螺絲標記:螺絲上可能有特殊的標記、標籤或刻印,以識別螺絲類型、規格或製造商。

夾緊螺絲:用於夾緊零件,通常有特殊的設計,以提供更大的壓力和力量。

快速連接螺絲:具有快速連接功能,可快速連接和斷開,通常用於需要經常拆卸的應用。

特殊形狀頭部螺絲:螺絲頭部可能具有特殊形狀,如球形、錨形、梅花形等,以滿足特定的連接需求。

每種特殊螺絲都具有獨特的特點,用途各異,通常根據具體的工程和製造需求來選擇。選擇正確的特殊螺絲是確保項目成功的重要一步,它們可以根據性能、材料、形狀和功能等因素進行選擇。

Special screws are screws with special specifications that help solve a variety of problems in modern industry and engineering. The characteristics of special screws are: their special shape can provide strong fit and enhanced shock resistance, and their appearance also has high aesthetics and reliability.

Special screws can be used for various purposes, such as: mechanical equipment, building materials, tools

We are a professional screw manufacturer that provides design and manufacturing services for special screws. We can design and produce special screws according to customers' special requirements. Special screws with special shapes, special materials, special sizes and special surface treatments can be manufactured to meet customers' special requirements.

In addition, the design and manufacturing process of special screws also requires multiple steps, including: first, the professional screw manufacturer will design the special screw drawings according to certain specifications according to the special requirements of the customer; secondly, the professional screw manufacturer will design the special screw drawings according to the customer's special requirements; According to the designed drawings, the parts of the special screws are processed; finally, a professional screw manufacturer will assemble these parts to complete the manufacturing of the special screws.

In general, special screws are screws with special specifications used to solve various problems. They can be used for various purposes and can be designed and manufactured according to customers' special requirements. Professional screw manufacturers also provide special screw-related services to provide customers with the highest quality products and services.

The term "specialty screws" is generally used to describe screws that have a special design, size, shape or purpose other than standard screws. These screws are often custom-made or manufactured to meet specific engineering, manufacturing, or application needs. Here are some examples of what may be special screws:

Special material screws: Some special applications require the use of very special material screws, such as high-temperature alloys, ceramic screws, composite material screws, etc. These material screws can work in extreme environments such as high temperatures, corrosion or special chemical environments.

Special Size Screws: Some projects require non-standard size screws, which may be very small or very large, to meet specific manufacturing needs.

Self-tapping screws: Self-tapping screws usually have a sharp tip that allows them to drill holes directly into the surface of the material without drilling a hole first. These screws are commonly used in metal, plastic, and wood to allow for quick connections.

Screws: Screws are commonly used in woodworking projects and they have a special thread design to provide better grip and retention.

Internal and external screws: Internal screws are usually hollow, while external screws are screws with holes inside. These screws are usually used for special connection needs, such as modular furniture.

Anti-theft screws: These screws are specially designed for added security and are often used to protect property or equipment from theft.

Special head screws: Screws with special heads, such as hex head, star head, saucer head, etc., can provide different tightening methods and are suitable for different tools or applications.

Insulating Screws: Used in electronic or electrical applications, these screws are made with insulating material to prevent the flow of electrical current.

Specialty screws are available in a variety of designs and uses, depending on the specific application needs. If you need more specific information or have questions about a specific kind of special screw, please provide more background information and I will try to be more helpful.

When it comes to specialty screws, here are more possible examples and related information:

Micro Screws: These are very small screws that are often used in precision applications such as miniature electronics, watches, glasses, etc. Their size is usually measured in microns or submillimeter.

Wave Screws: These screws have corrugated or gear-like threads and are often used in applications that need to be prevented from loosening on their own, such as bicycle screws, automotive screws, etc.

Optical Screws: In optical equipment and instruments, highly precise screws are required to achieve precise focus and alignment.

Thermal Screws: Used for specialized applications in high temperature environments, these screws are typically made from high-temperature alloys that provide stability in extreme temperatures.

Screws with waterproof seals: Where waterproof or sealing properties are required, these screws are often equipped with special sealing gaskets or coatings to ensure that materials cannot ingress or liquids cannot penetrate.

Specially Coated Screws: These screws may have anti-corrosion, anti-scratch, or other special coatings to increase their durability and performance.

Headless Screws: These screws are typically used in applications that require a flat or sharp end, such as when securing flat surfaces or special brackets.

Hinge screws: Used in applications with extended functionality, such as car door hinges or adjustable mechanical parts.

Structural Screws: Used in building and structural engineering, often with high strength and durability, to support structural elements.

Composite screw: A screw that has multiple functions or characteristics, such as a screw that has both anti-theft and insulating properties.

These are some examples of specialty screws, each with a specific design and purpose to meet a variety of different engineering and application needs. The use of specialty screws often requires careful consideration of their performance characteristics and materials to ensure they achieve the desired results.

Screw Rings: These screws have a ring-shaped top and are often used for hanging and fastening things. They are often used to hang chandeliers, paintings or other decorative items.

Vertical Lift Screws: These screws usually have automatic raising and lowering functions and are used in applications such as platform lifts, chair lifts, etc.

Anti-vibration screws: These screws often have springs or other shock-absorbing designs used to reduce vibration and shock, such as in mechanical and electronic equipment.

Rupture Screws: These screws are designed to automatically break when a specific torque or load is reached to provide a controlled safety feature, such as in a security system.

Special shape screws: Sometimes the top or threads of screws have non-standard shapes to meet special connection needs, such as U-shaped screws, T-shaped screws, etc.

Insulating Screws: These screws are often used in electrical or electronic applications to prevent the flow of electrical current or to provide insulating properties.

Self-drilling screws: These screws have special drill bits that simultaneously drill and secure while passing through the material, and are commonly used for metal and roof installations.

Adjustable screws: These screws have adjustable tops or threads, allowing the user to adjust the length or connection as needed.

High-Strength Screws: Designed for high-strength applications such as aerospace, automotive manufacturing, or construction engineering, often using special high-strength materials.

Screw hole plugs: These screws have the function of closing or plugging the screw hole to seal or prevent material from flowing out.

Stud screw: Two threaded tops, usually used to join two objects.

Specialty screws such as these come in a variety of features and uses and can be selected based on specific engineering and manufacturing needs. For special applications, the characteristics of screws often need to be carefully considered to ensure that they will achieve the required functionality and performance.

Security Screws: These screws are often specially designed and require special tools or techniques to remove for added security, often to prevent unauthorized opening or disassembly.

Wave Screws: These screws have a wavy thread and are used for special grip requirements, such as car tires.

Compression screws: Specially designed to create pressure in applications such as clamping elements.

Chain Screws: These screws have special connections that create an interlocking or chain structure.

Fine Thread Screws: Screws with very fine threads are used for special precision applications such as optics and instrumentation.

Locking screw: It has a self-locking function to prevent it from loosening during vibration or movement.

Embedded Screws: Used to embed and secure in materials, typically found in composites or plastics.

Thermal screws: used in high-temperature applications and resistant to high temperatures, such as during heat treatment.

Rubber Pad Screws: Screws with rubber pads to provide sealing or shock absorption.

High Precision Screws: Very precisely manufactured and used in applications that require a high degree of accuracy, such as aerospace and medical equipment.

Anti-corrosion screws: Specially treated to improve their resistance to corrosion, typically used in humid or corrosive environments.

These are some examples of specialty screws, all with different designs and features to suit the needs of various specific applications. Choosing the right specialty screw depends on the specific project and use case, often based on engineering requirements and performance needs.

Iron Screws: These screws are commonly used in carpentry and construction applications and are highly resistant to corrosion and tensile strength.

Turnbuckle: A special design with screw holes and screws, often used to clamp or secure objects.

Automation screws: Used in automated assembly systems, they can be automatically locked or tightened to improve production efficiency.

Hollow screws: have a hollow design and are often used in lightweight designs or applications where weight reduction is required.

Specially Coated Screws: Features anti-corrosion, anti-scratch, or other special coatings to provide extra protection and durability.

Painted Screws: Used in applications where the screws need to match the appearance of the surrounding material, such as furniture assembly.

Screw markings: Screws may have special markings, labels, or engravings to identify the screw type, gauge, or manufacturer.

Clamping Screws: Used to clamp parts, often specially designed to provide greater pressure and force.

Quick Connect Screws: Features a quick connect feature that enables quick connection and disconnection, typically used in applications that require frequent disassembly.

Special shape head screws: Screw heads may have special shapes, such as ball, anchor, plum blossom, etc., to meet specific connection needs.

Each specialty screw has unique characteristics, is used for a variety of purposes, and is often selected based on specific engineering and manufacturing needs. Choosing the right specialty screws is an important step in ensuring a successful project, and they can be chosen based on factors such as performance, material, shape, and function.